CNC bending transforms how you approach custom parts, allowing for precision and creativity like never before. This method not only enhances your design capabilities but also guarantees consistency across all pieces. Imagine having the flexibility to tweak designs quickly while managing costs effectively. It’s a game changer for marketers and designers. But what specific advantages does it offer, and how can it elevate your next project? Let’s explore further.

Key Takeaways

- CNC bending allows precise control over angles and dimensions, enabling marketers and designers to create tailored, high-impact custom parts.

- The technology produces consistent results, ensuring quality and uniformity across all custom components for effective branding and marketing.

- CNC bending significantly reduces production time, allowing for quicker turnarounds on custom designs and meeting tight deadlines efficiently.

- It minimizes material waste, optimizing budgets and maximizing ROI for marketers and designers while maintaining high design standards.

- The versatility of CNC bending accommodates various materials and complex shapes, fostering innovation and creativity in custom part design.

Understanding CNC Bending: A Game Changer for Custom Parts

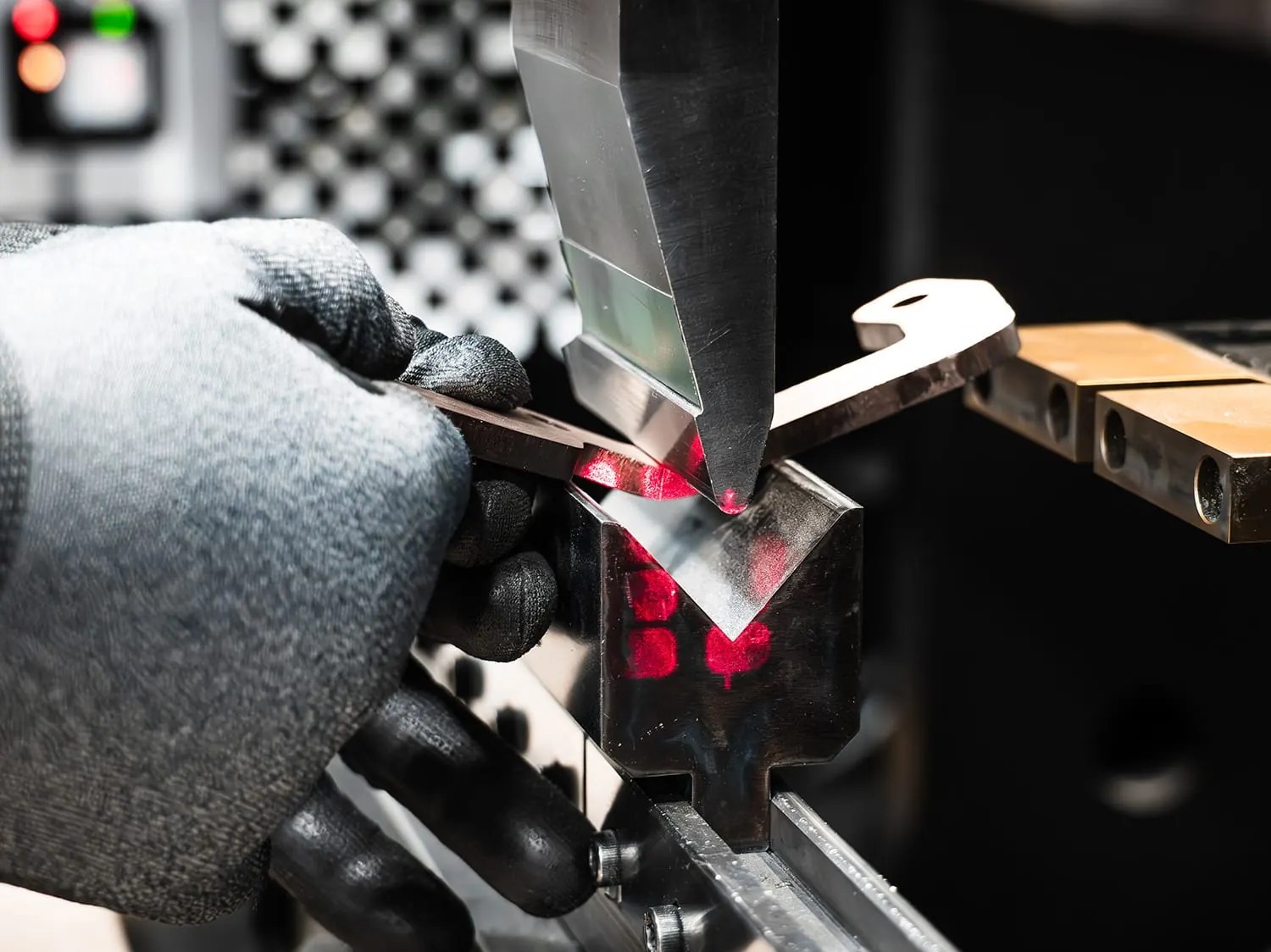

When you consider the complexities of creating custom parts, CNC bending emerges as a pivotal solution that transforms traditional manufacturing methods. With its precision and efficiency, you can achieve intricate designs that truly reflect your vision. One of the key benefits of CNC bending for custom parts is its ability to produce consistent results, minimizing waste and reducing costs. You’ll also appreciate the flexibility it offers; whether you need a single prototype or a large production run, CNC bending adapts to your needs seamlessly. Additionally, the technology allows for quick adjustments during the process, ensuring that your final product meets exact specifications. Embracing CNC bending connects you to a community of innovators committed to pushing the boundaries of custom manufacturing.

Key Advantages of CNC Bending for Marketers and Designers

CNC bending offers numerous advantages that can greatly enhance your marketing and design efforts. By embracing this technology, you can create custom parts that truly resonate with your audience. Here are some key benefits of CNC bending for custom parts:

- Precision: Achieve exact measurements for flawless designs.

- Consistency: Maintain uniformity across all parts, ensuring quality.

- Speed: Reduce production time, allowing for quicker turnarounds.

- Versatility: Work with various materials and complex shapes effortlessly.

- Cost-Effectiveness: Minimize waste and optimize your budget, maximizing ROI.

These benefits of CNC bending for custom parts empower you to push creative boundaries, engage your target market, and craft unique solutions that stand out. With CNC bending, you’re not just designing; you’re shaping experiences.

Enhancing Design Flexibility With CNC Bending

As you explore the possibilities of custom parts, you’ll find that CNC bending markedly enhances design flexibility. This technology allows you to create complex shapes and intricate designs that traditional methods can’t match. With precise control over angles and dimensions, you can easily adjust your designs to meet specific requirements, ensuring that every detail aligns with your vision. CNC bending also supports a variety of materials, making it easier to experiment and innovate without limitations. Whether you’re crafting unique prototypes or final products, you can achieve stunning results that resonate with your audience. The benefits of CNC bending for custom parts empower you to push boundaries and create pieces that truly reflect your brand’s identity and message.

Cost-Effectiveness and Efficiency in Custom Part Production

While traditional manufacturing methods often lead to high costs and lengthy production times, CNC bending revolutionizes custom part production with its cost-effectiveness and efficiency. As you explore this innovative approach, you’ll find several benefits of CNC bending for custom parts:

- Reduced material waste, maximizing your budget

- Faster turnaround times, meeting tight deadlines

- Lower labor costs through automation

- Precision that minimizes rework and errors

- Versatility for various designs and materials

Embracing CNC bending means you can focus on creativity without the burden of excessive expenses. You’ll have the ability to produce tailored parts that resonate with your audience while maintaining efficiency. This blend of cost-effectiveness and innovation positions you to thrive in today’s competitive landscape.

Real-World Applications: Success Stories of CNC Bending in Action

When you plunge into the world of CNC bending, you’ll discover an array of success stories that highlight its transformative impact on custom part production. Take, for instance, a furniture designer who used CNC bending to create sleek, modern chairs. By customizing metal components, they achieved a unique aesthetic while maintaining structural integrity. In another example, a marketing team crafted eye-catching display stands that enhance brand visibility at trade shows, thanks to precise bending techniques. These stories illustrate the benefits of CNC bending for custom parts, enabling you to push creative boundaries, streamline production, and foster collaboration. Embrace these innovations, and you’ll find new ways to connect with your audience and truly stand out in a competitive market.

Frequently Asked Questions

What Materials Can Be Used in CNC Bending Processes?

You can use various materials in CNC bending processes, including aluminum, steel, copper, and brass. Each material offers unique properties, allowing you to create customized parts that meet specific design needs and performance requirements.

How Does CNC Bending Compare to Traditional Bending Methods?

CNC bending offers precision and repeatability that traditional methods can’t match. You’ll find it’s faster, reduces waste, and allows for complex designs, making it a superior choice for creating custom parts efficiently and accurately.

What Industries Benefit Most From CNC Bending for Custom Parts?

You’ll find industries like automotive, aerospace, and architecture benefit most from CNC bending for custom parts. Their needs for precision, efficiency, and adaptability align perfectly with the capabilities of CNC bending technology, enhancing overall production quality.

Can CNC Bending Accommodate Complex Geometries and Designs?

Yes, CNC bending can easily accommodate complex geometries and designs. You’ll find it enhances creativity, allowing you to craft unique, high-quality custom parts that meet your specific project needs and stand out in your industry.

What Is the Typical Turnaround Time for CNC Bending Projects?

Typical turnaround time for CNC bending projects ranges from a few days to several weeks, depending on complexity and volume. You’ll find that efficient planning and communication can greatly streamline the process, ensuring timely delivery.

Conclusion

To sum up, CNC bending isn’t just a manufacturing method; it’s a transformative tool that empowers you to craft bespoke, high-impact parts that resonate with your brand. By leveraging its precision and flexibility, you can push creative boundaries, streamline production, and ultimately captivate your audience. Whether you’re designing intricate components or optimizing costs, embracing CNC bending could be the key to elevating your marketing and design efforts to new heights. Don’t miss out on this game-changing opportunity!

You May Also Like To Read: